-

Call

-

-

Address

Gat No 261, Moshi -Alandi Rd,

Moshi, Pune-412105

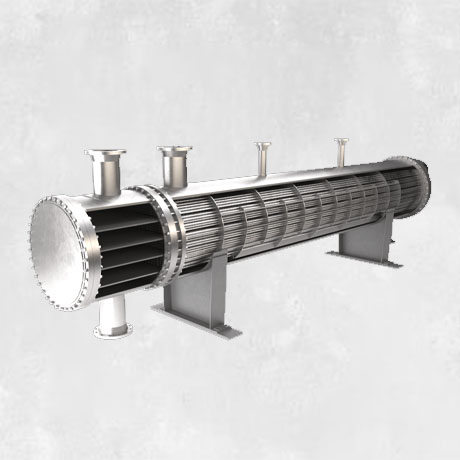

Heat Exchangers

Heat Exchangers

A heat exchanger is a piece of equipment that continually transfers heat from one

medium to another in order to carry process energy.

Heat exchangers are used to transfer heat between two sources. The exchange can

take place between a process stream and a utility stream (cold water, pressurized steam,

etc), a process stream and a power source (electric heat), or between two process streams

resulting in energy integration and reduction of external heat sources. Typically, a heat

exchanger is used with two process streams.

The term heat exchanger applies to all equipment used to transfer heat between two

streams. However, the term is commonly used to equipment in which two process streams

exchange heat with each other. In the other hand, the term heater or cooler is used when

the exchange occurs between a process stream and a plant service stream. Exchangers can

also be classified as fired (heat source is fuel combustion) and unfired exchangers.

Design Standard : TEMA (Tubular Exchanger Manufacturers Association)

There are many types of heat exchangers applied in the process industry. These types include :

- Shell and Tube Exchangers

- Plate-fin Exchangers

- Spiral Heat Exchangers

- Air Coolers and Condensers

- Hairpin / Double Pipe Exchangers

- Fired Heaters